-

Servizi dello stampaggio ad iniezione

-

Servizio di plastica dello stampaggio ad iniezione

-

Stampaggio ad iniezione doppio del colpo

-

stampaggio ad iniezione di precisione

-

Stampaggio ad iniezione del singolo colpo

-

Stampaggio ad iniezione di Overmolding

-

stampaggio ad iniezione dell'OEM

-

inserisca lo stampaggio ad iniezione

-

Stampaggio ad iniezione di elettronica

-

Stampaggio ad iniezione del silicone

-

Il servizio della pressofusione

-

RecebIl cliente vi vuole produrre il loro prodotto perché erano felici con i risultati con le vostre precedenti produzioni.

RecebIl cliente vi vuole produrre il loro prodotto perché erano felici con i risultati con le vostre precedenti produzioni. -

SeanBuon lavoro di squadra – buoni fornitori, azioni veloci e buona gente da entrambi i lati che lavorano insieme…. Grazie.

SeanBuon lavoro di squadra – buoni fornitori, azioni veloci e buona gente da entrambi i lati che lavorano insieme…. Grazie. -

ChrisI ringraziamenti per preoccuparsi abbastanza da reagire, pensano diversamente ed innovano con noi – qui ancora in questa occasione per trovare questa alternativa – molto apprezzata da noi in RnD,

ChrisI ringraziamenti per preoccuparsi abbastanza da reagire, pensano diversamente ed innovano con noi – qui ancora in questa occasione per trovare questa alternativa – molto apprezzata da noi in RnD,

Precision Injection Molding Services with ±0.01mm Tolerance and Custom Color Options Using KLM Tooling Base

Contattimi gratis campioni e buoni.

WhatsApp:0086 18588475571

wechat: 0086 18588475571

Skype: sales10@aixton.com

Se avete di preoccupazione, forniamo la guida in linea di 24 ore.

x| Application | Injection Molding Parts | Base | KLM Tooling Base |

|---|---|---|---|

| Runner | Hot Runner\ Cold Runner | Finish | None |

| Tolerance | ±0.01 Mm To ±0.1 Mm | Color | Black Customized Color |

| Mold Base | LKM, HASCO, DME | Surface Finish | Matte, Glossy, Textured, Painted |

| Evidenziare | ±0.01mm Tolerance Injection Molding Services,Custom Color Options Thermoplastic Molding Service,KLM Tooling Base Plastic Fabricating Service |

||

Product Description:

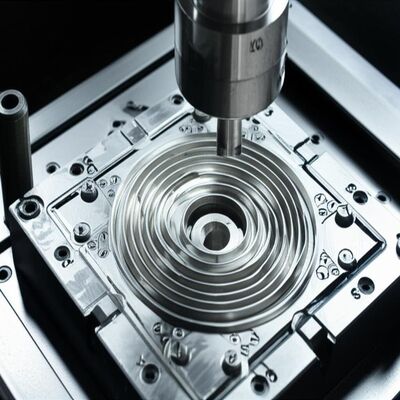

Our Injection Molding Services provide a comprehensive solution for businesses and manufacturers seeking high-quality thermoplastic molding service. Utilizing advanced equipment such as CNC machines, EDM, and wire-cutting technology, we ensure precision and efficiency in every project. With a strong foundation based on the reputable KLM Tooling Base, our injection molding capabilities are designed to meet diverse industry needs and specifications.

We specialize in producing parts through a meticulous injection forming service that transforms raw thermoplastic materials into durable, finely detailed components. This process is ideal for creating complex shapes and designs with consistent quality, making it a preferred choice for industries ranging from automotive to consumer electronics. Our skilled team works closely with clients to deliver customized solutions that align with their unique requirements.

One of the standout features of our injection molding service is the availability of custom color options. We understand that color customization plays a vital role in branding and product differentiation, so we offer a wide range of color choices to match your exact specifications. Whether you require vibrant hues or subtle shades, our plastic fabricating service can accommodate your preferences and ensure the final product meets your aesthetic expectations.

In addition to color customization, we prioritize the safe and secure packaging of all molded parts. Our suitable safe packaging methods are designed to protect your products during transportation and storage, minimizing the risk of damage and ensuring that they arrive in pristine condition. This attention to detail reflects our commitment to quality and customer satisfaction throughout the entire production and delivery process.

Our injection molding capabilities are supported by state-of-the-art machinery and a dedicated team of experts who bring years of experience in thermoplastic molding service. From initial design consultation to final production, we maintain stringent quality control measures to guarantee that each component meets the highest standards. This comprehensive approach not only enhances product reliability but also optimizes production efficiency, reducing lead times and costs.

While our injection molding service offers a range of finishes, the standard finish for our products is none, providing a clean and precise surface that can be further customized or treated as needed. This flexibility allows clients to apply secondary processes such as painting, plating, or coating according to their specific application requirements.

Our plastic fabricating service extends beyond injection molding, offering clients a complete suite of manufacturing solutions. By integrating CNC machining, EDM, and wire-cutting technologies, we can handle complex tooling and intricate mold designs that other providers might find challenging. This integration ensures that every mold we produce is optimized for performance and longevity, contributing to superior end-product quality.

Choosing our Injection Molding Services means partnering with a provider dedicated to excellence in thermoplastic molding service, plastic fabricating service, and injection forming service. We combine technical expertise, advanced equipment, and a customer-centric approach to deliver products that exceed expectations. Whether you need prototype development, small batch production, or large-scale manufacturing, our services are adaptable to your project scale and complexity.

In summary, our Injection Molding Services stand out for their precision, customization options, and commitment to quality. Backed by the KLM Tooling Base and equipped with cutting-edge technology, we offer reliable and efficient thermoplastic molding service solutions tailored to your needs. With custom color options, suitable safe packaging, and a focus on delivering flawless injection forming service, we are your ideal partner for all plastic fabricating service requirements.

Technical Parameters:

| Surface Finish | Matte, Glossy, Textured, Painted |

| Tolerance | ±0.01 Mm To ±0.1 Mm |

| Package | Suitable Safe Packaging |

| Equipment | CNC, EDM, Wire-Cutting, Etc. |

| Product Material | Plastic |

| Mold Base | LKM, HASCO, DME |

| Design Software | UG, Pro/E, AutoCAD, Solidworks |

| Finish | None |

| Application | Injection Molding Parts |

| Mold Life | 300,000-500,000 Shots |

Our Injection Molding Services provide high-quality Thermoplastic Molding Service solutions, utilizing advanced equipment and design software to ensure precision and durability. We also offer Thermoforming Service options tailored to meet diverse industrial needs.

Applications:

OEM's Injection Molding Services are designed to cater to a wide range of application occasions and scenarios, making them an ideal choice for industries requiring precision plastic components. Certified with ISO90001, our services ensure top-quality standards, giving clients confidence in every order. Whether you need a single prototype or mass production, our minimum order quantity of just 1 set allows for flexibility and customization to meet diverse project needs.

Our injection molding services are highly suitable for manufacturing complex plastic parts used across automotive, electronics, medical devices, consumer goods, and industrial equipment sectors. Utilizing advanced equipment such as CNC machines, EDM, and Wire-Cutting technology, we guarantee precision and consistency in every mold we produce. The mold bases from reputed brands like LKM, HASCO, and DME further enhance the quality and durability of the molds, ensuring long-term reliability for your production runs.

In scenarios where timely delivery is critical, OEM offers a reliable supply ability of 10 sets per month with a delivery time frame of 45-50 days. This efficient turnaround supports businesses in maintaining their production schedules without compromising on quality. Our payment terms via T/T provide secure and straightforward transactions, while pricing remains negotiable to accommodate varying project scopes and budgets.

Packaging is another crucial factor in our service offering. We use metal pallets and suitable safe packaging techniques to protect your injection molded parts during transit, minimizing risks of damage and ensuring your products arrive in perfect condition. This robust packaging solution is especially important when shipping delicate plastic extrusion service components across long distances.

Our injection molding services perfectly complement Plastic Extrusion Service processes. Many industries rely on a combination of injection molding and plastic extrusion service to produce complex assemblies and parts with superior performance characteristics. Whether you require intricate injection molded plastic parts or components created through plastic extrusion service, OEM provides comprehensive solutions tailored to your specific manufacturing requirements.

In summary, OEM's Injection Molding Services are ideal for any project requiring high-quality, precise plastic parts with flexible order quantities, certified quality assurance, and dependable delivery schedules. With advanced equipment, trusted mold bases, and professional packaging, we support a broad array of application occasions and scenarios, including those integrating plastic extrusion service processes, to deliver superior plastic components for your business needs.

Customization:

Our OEM Injection Molding Services offer comprehensive product customization with a focus on quality and precision. Certified under ISO90001, we ensure reliable Thermoplastic Molding Service tailored to your specific needs. We accept a minimum order quantity (MOQ) of 1 set, providing flexibility for various project sizes. Pricing is negotiable to accommodate your budget requirements.

We specialize in Plastic Fabricating Service using high-quality plastic materials, maintaining tight tolerances from ±0.01 mm to ±0.1 mm to guarantee exceptional accuracy. Our Injection Forming Service supports custom colors, including black and other customized color options, with no additional finish applied.

Packaging is handled with care using sturdy metal pallets to protect your products during transit. Delivery time typically ranges from 45 to 50 days, supported by a supply ability of 10 sets per month. Payment terms are convenient, accepting T/T for smooth transactions. Our molds have a long life span of 300,000 to 500,000 shots, ensuring durability and consistent performance.